Feeding Equipment

Material feeding equipment is essential for managing the controlled flow of bulk materials in industrial processes. Pro-Quip provides high-quality feeding solutions such as screw feeders, vibratory feeders, grizzly feeders, and batch chargers, designed to optimize material handling with precision and automation. These systems ensure consistent material supply, reduce waste, and enhance process efficiency.

Precision Feeding Solutions for Every Industry

Applications of Feeding Equipments

-

Glass Industry – Used for batch charging and precise material feeding in glass melting.

-

Cement & Foundry – Facilitates controlled feeding of raw materials into crushers and processing units.

-

Chemical & Pharmaceutical – Ensures accurate dosing and transfer of acceptable materials or powders.

-

Food & Agro Processing – Maintains hygienic and efficient bulk material transfer in food production.

Benefits of Material Feeding Equipment

-

High Precision & Accuracy – Ensures precise material flow, reducing waste and enhancing efficiency.

-

Boosted Automation & Productivity – Automates feeding to minimize labor and maximize output.

-

Versatile Applications – Serves industries like glass, cement, chemicals, pharma, food, and agro-processing.

-

Robust & Durable – Built for long-term industrial use with minimal downtime.

-

Custom Solutions – Tailored systems to meet specific industry needs.

-

Low Maintenance & Reliable – Easy to maintain for uninterrupted operations.

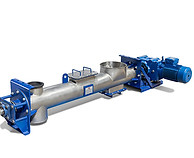

Batching Screw Feeder

A Batching Screw Feeder ensures accurate dosing of bulk materials using a helical screw mechanism, ideal for mixing and batching in industries like food, pharma, and chemicals.

Key Features

-

Screw Design – Single/twin screws with variable pitch for precise feeding.

-

Operation & Control – Compatible with controllers, load cells & PLCs for full automation.

-

Technical Specs – Anti-bridging hoppers, VFD motors; handles powders, granules & pellets.

-

Maintenance & Safety – Easy to clean with overload protection & emergency stop features.

Batch Charger

A Batch Charger is a device used in industries like glass manufacturing to feed raw materials into melting furnaces with precision. It ensures a consistent feed rate, uniform material distribution, and adjustable flow control for efficient melting.

Key Features

-

Material Feeding: Provides a steady supply of raw materials.

-

Uniform Distribution: Ensures even melting.

-

Flow Control: Adjusts material flow as needed.

Grizzly Feeder

A Grizzly Feeder is an industrial device that regulates the flow of bulk materials into crushers or processing equipment. It ensures a steady feed rate while pre-screening smaller particles to improve efficiency.

Key Features

-

Material Feeding: Provides controlled bulk material flow.

-

Pre-Screening: Separates fine particles before processing.

-

Adjustable Grizzly Bars: Customizable material size control.

-

Durable Construction: Built with high-strength steel and wear-resistant liners.

-

Variable Speed Control: Uses electric motors with adjustable vibration frequency.

Electro-Mechanical Vibratory Feeder

An Electro-Mechanical Vibratory Feeder is an industrial device designed to move and control the flow of bulk materials in various processes. Proquip offers a range of models and customization options to suit diverse industrial needs.

Key Features

-

Capacity – Ranges from a few kg to several tons per hour.

-

Vibration Mechanism – Electro-mechanical drives ensure consistent, adjustable vibrations.

-

Construction – Heavy-duty build for durability and tough operations.

-

Customization – Multiple models tailored to specific handling needs.

Electro-Magnetic Vibratory feeder

An Electro-Magnetic Vibratory Feeder utilizes electromagnetic energy to generate vibrations, facilitating the precise movement and control of bulk materials in various industrial processes.

-

Electromagnetic Drive – Provides consistent vibratory motion.

-

Vibratory Tray – Made from SS or MS for varied applications.

-

Controller – Adjusts amplitude & frequency for precise control.

-

Adjustable Feed Rate – Simple voltage-based adjustment.

-

Low Maintenance – Minimal moving parts for easy upkeep.

-

Energy Efficient – Lower power use than mechanical feeders.

Silo (Stheler Bin)

A Silo (Stheler Bin) is a transfer storage unit designed to handle bulk materials that are challenging to manage with conventional equipment or in spaces with limitations. It offers a maintenance-free solution for transferring such materials.

Key Features

-

Material: Constructed from carbon steel or stainless steel.

-

Capacity: Ranges from 1 to 5 tons.

-

Dimensions: Diameter typically between 0.5 to 3 meters; height from 1 to 3 meters.

-

Discharge Mechanism: Automatically discharges material by gravity when positioned on the main storage silo.

How Automation Enhances Performance

At Pro-Quip, we design intelligent automation systems that maximise efficiency and minimise manual intervention. Our solutions are scalable, robust, and user-friendly, tailored to meet the specific needs of each application.

Key Features:

💡 PLC Control Panels – Compact, logic-driven control for complex operations.

📊 SCADA Systems – Real-time monitoring and centralised dashboards.

⚡ VFD & MCC Integration – Precise motor control and streamlined power management.

🔔 Safety & Diagnostics – Fault detection, alerts, and remote diagnostics to cut downtime.

Every solution is custom-built for seamless integration, higher output, and smarter performance.